wind turbine

This was my second time using Fusion360, and I will say it was a big improvement from before. I set out to

make a vertical wind turbine connected to a generator to produce an electrical current. It had to be small

and able to come apart to transport. I wanted the energy generated to power an LED for a simple way to

show that it works. My main resource for construction would be 3D printing with PLA. Although I have

learned basic electromagnetism in Advanced Higher Physics, I had a very limited understanding of how to

create a motor or generator so I researched by watching a lot of videos and reading articles.

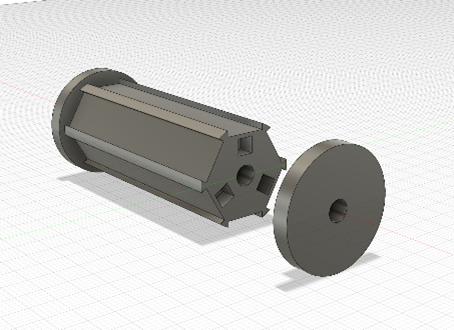

After recently learning skills in Fusion360, I used that to create a design for the generator. Six

rotating neodymium magnets with a stationary copper coil around them. The print would be in four parts to

not use supports: the main component for the magnet rotor, the cap for the magnet rotor, and two halves

for the coil. The magnets would be placed in each slot with alternating poles. A five-millimetre hole was

through the rotor for the axle, and an eleven-millimetre hole was through the copper for the two bearings.

I created a sketch on Fusion360 with the circular pattern function.

Unfortunately, I ran into a problem where one of the magnets shattered into two pieces which resulted in a

redesign with four magnet slots instead.

Unfortunately, after assembly, it did not work. This was just my first attempt, though. I packed it up and

learned from it.

This design did not work after testing with a multimeter and a drill, but I learned from my mistakes. It

produced very little power when it did work. My reasoning for this was that the distance between the

magnet and the coil was too great and they needed to be closer to generate energy. I think a higher number

of turns in the coil is needed for everything to be cleaner and tighter, as there is a reasonable amount

of friction. It wouldn't have been easy to turn with just wind, so I would need a gear ratio for more

torque, but then it wouldn't move fast enough to produce anything. I started again with some more

knowledge than before and researched some more.

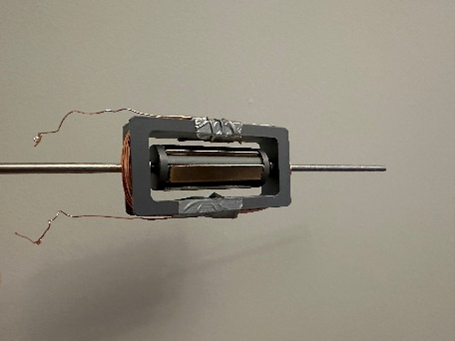

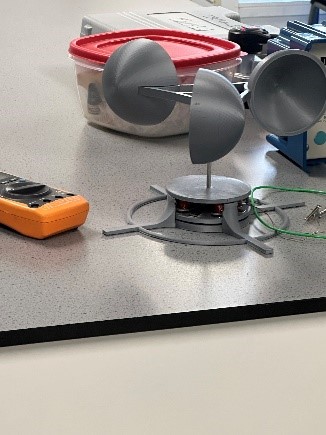

Creating another design. This time with eight half-sized magnets and four coils, they were much closer

together with one millimetre between them, and the coils were much tighter. I then printed out each piece

and made a few extra buffer parts to make sure everything sat right with minimal friction. I superglued

all the parts together. It worked on the same idea of having the magnets rotate while the copper wire was

stationary, generating AC current.

Testing it gave 50 mV, which was significantly more than the last one. Though not enough to power an LED

of around 1.8V, it is still generating energy. This was turning it by hand at a reasonable speed. In the

actual wind turbine, I intend to have a gear ratio that would increase the angular velocity

considerably.

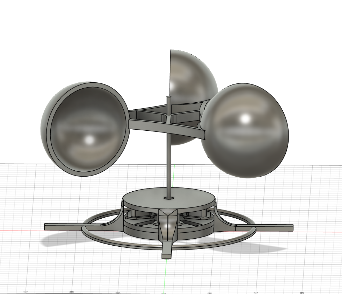

Next was creating the windmill. I opted for a vertical design as I found it was more unique and

interesting than a horizontal windmill. I used Fusion360 again to design it. I went for a simple design of

three semi-spheres attached to a centre axle. It would be printed in 4 separate parts. The semi-spheres

have a slot where the centre body would fit in and then be superglued.

The air would flow around the back of the semi-spheres and be caught on the other side, creating rotation.

The hole in the centre of the windmill is a 5mm diameter and is where a steel axle is placed. Each

semi-sphere took nearly nine hours of printing. I used minimal supports on the interior, though it would

take 73% fewer supports to have it on the exterior, the exterior being smooth is more valuable than the

interior, as it is just used to catch the air and not flow around it. The supports will leave a rough

surface even with aggressive sanding, as the printed filament is not as densely packed as it were without

supports. The infill on the rest of the wind turbine was 15% for rigidity but for the spheres it was

lowered to 5% and the centre to 10%. The lighter the wind turbine is the easier it will be to rotate. The

centre was at a higher infill because of the already thin design of it to minimise weight.

I used an old design of a cover that didn't fully work as the design was faulty. The windmill part worked

fantastically with little friction; testing outside, it only moved in one direction as planned, and air

blew right around the back of each semi-sphere. I then started to design a new cover that would be more

open, wouldn�t touch the rotating part, and would have a large, stable base so the force of the wind

wouldn�t tip it. I also wanted it to have lots of areas to attach zip-ties to anything.

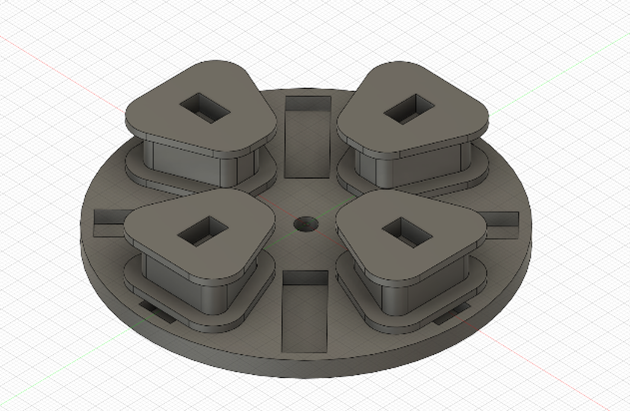

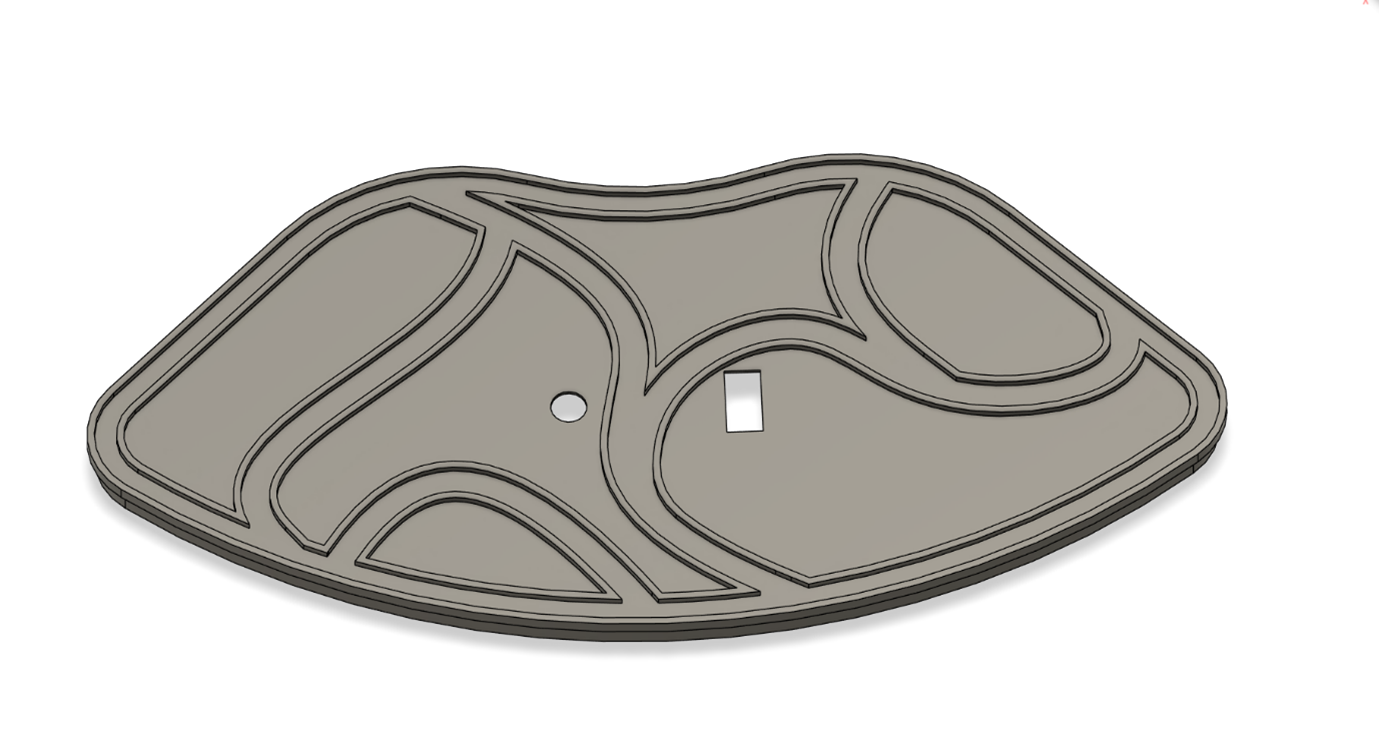

I created this design on Fusion360; the hole in the centre is 11 mm in diameter for a bearing to sit in,

and the two inner rings around the centre are for the rotor to balance off of but not touch most of the

time. The four surrounding stabilisers are to hold the coils of wire in place, as the extruding wires will

not be able to pass the stabilisers. Then there are two outer rings with the four legs; these were to

stabilise the whole thing, and as there are lots of holes, you can use the zip-ties on any part.

I constructed the whole thing and tested it. It only gave 0.02V when hand spinning. I was quite

disappointed, so I looked into each part. The problem is that the copper wire coiled in the middle was not

enamelled like I previously thought. Effectively, the current would short across the coil and not keep the

current inside the turns of the wire, so there were no turns of the wire. The turns of the wire in this

are very crucial. Re-coiled the centre with thinner enamelled wire, 0.40mm, compared to the previous

0.8mm. Each coil had approximately 200 turns of wire instead of 50. Testing this gave 2.1V, significantly

more than before, and it still works outside with normal winds.

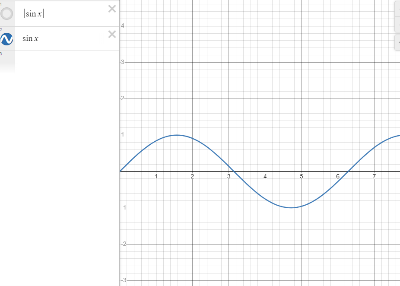

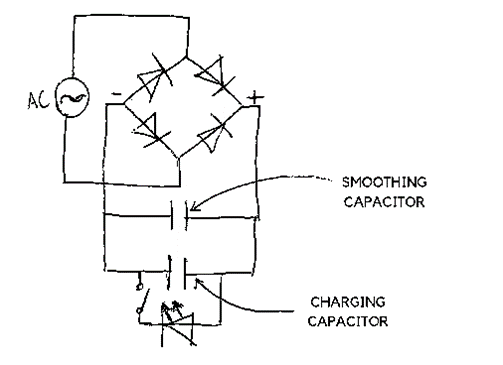

The next step was to create a full bridge rectifier to turn the alternating current into direct current so

that it could be used for an LED. An alternating current graph of voltage against time would look like

this.

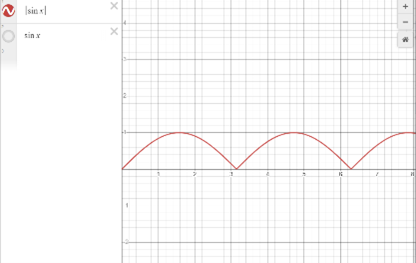

Just using a diode to only allow the current to travel one way would give you a pulsating graph where it

is only producing a voltage half of the time. Using a full bridge rectifier would allow the current to

travel in one direction all the time. Producing a graph like this.

Just using a diode to only allow the current to travel one way would give you a pulsating graph where it

is only producing a voltage half of the time. Using a full bridge rectifier would allow the current to

travel in one direction all the time. Producing a graph like this.

Then a capacitor can be inserted to “smooth” out the voltage, so it is a direct current. I made sure to

create a circuit diagram before soldering.

The LED will then turn on whenever the switch is closed as the capacitor is then discharged through the

LED with a bright flash and a slow dim.

I tested with a variety of capacitors and found the best ones to work for me. Then of course the wires

would be hanging form the turbine and not very pretty. So, I designed a casing for the electric components

that would fit onto the stand of the turbine.

This fit snuggly onto the stand and had a small divot for the enamelled wire to enter. The lid for the

case took a few attempts as it has to fit the LED and switch so they wouldn't move. I opted on small

divots for the LED and switch so they can be glued in close to the surface, and on the

top, it has a design inspired by the infill of all the prints so far.

As I had to make sure everything could be taken apart into their individual pieces, after lots of stress

testing, the wind catcher started slipping down the steel axle. So I printed a small attachment to stop

the axle from going through the top.

This was the final part.

The whole process showed me how much effort is put into each very simple component. The final product is a

very simple design that is very easy to assemble and disassemble. It was a very fun build despite the

problems, and I am very happy with the end result.